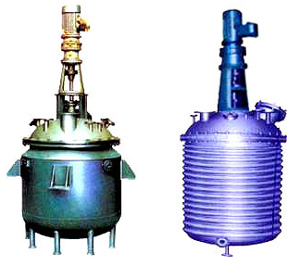

| Stainless Steel Kettle | | |

Our stainless steel kettle (electric, steam and thermal oil heating) is composed by cover, cylinder, jacket, stirrer,  gland seal drive and support. The body and parts contacting with the materials are all made by Ocr18Ni9 or 1Cr18Ni9Ti acid-resisting stainless steel plate. gland seal drive and support. The body and parts contacting with the materials are all made by Ocr18Ni9 or 1Cr18Ni9Ti acid-resisting stainless steel plate.

We are the professional stainless steel kettle manufacturer as well as all specifications of non-standard chemical and light mechanical equipment designer and producer. Welcome the enquiries both from home and abroad.

The stirrer of our kettle includes various types of traditional blade, turbo, impeller, anchor, gate, helical ribbon and sawteeth disk.

We specially recommend high cuts emulsifying kettle and stirring kettle set of gate stir, high cuts mulser and wall cleaner. The outstanding advantages are to integrate the functions of dispersing, mix, emulsification, homogenization and smash for extremely tiny particle, superior quality and efficiency. |

| ¡¡¡¡Stainless Steel Electric Heating Kettle |

| Nominal Volume L |

Electric

Power |

Size of Inner Kettle

¦Õmm |

Jacket Size

¦µmm |

Reducer Model |

Electromotor

n/kw |

Stirring Speed

r.p.m |

| 50 |

4¡Á2 KW |

¦Õ400 |

¦Õ600 |

BLD 0.8-1 |

1450/0.8 |

60-100 |

| 100 |

6¡Á2 KW |

¦Õ500 |

¦Õ700 |

BLD 1.1-1 |

1450/1.1 |

60-100 |

| 300 |

6¡Á4 KW |

¦Õ800 |

¦Õ1000 |

BLD 2.2-2 |

1450/2.2 |

60-100 |

| 500 |

9¡Á4 KW |

¦Õ900 |

¦Õ1100 |

BLD 3-2 |

1450/3 |

60-100 |

| 1000 |

12¡Á4 KW |

¦Õ1200 |

¦Õ1400 |

BLD 4-3 |

1450/4 |

60-100 |

| 2000 |

15¡Á5 KW |

¦Õ1400 |

¦Õ1600 |

BLD 4-3 |

1450/4 |

60-100 |

| 3000 |

15¡Á6 KW |

¦Õ1600 |

¦Õ1800 |

BLD 5.5-3 |

1450/5.5 |

60-100 |

|

| ¡¡¡¡Stainless Steel Steam Heating Kettle |

| Nominal Volume L |

Electric

Power |

Size of Inner Kettle

¦Õmm |

Jacket Size

¦Õmm |

Reducer Model |

Electromotor

n/kw |

| 30 |

400 |

500 |

0.6 |

BLD 0.6-1 |

60-100 |

| 50 |

500 |

600 |

0.8 |

BLD 0.8-1 |

60-100 |

| 100 |

550 |

65 |

1.1 |

BLD 1.1-1 |

60-100 |

| 150 |

600 |

700 |

2.2 |

BLD 2.2-2 |

60-100 |

| 200 |

650 |

750 |

2.2 |

BLD 2.2-2 |

60-100 |

| 300 |

800 |

900 |

3 |

BLD 3-2 |

60-100 |

| 500 |

900 |

1000 |

3 |

BLD 3-2 |

60-100 |

| 800 |

1100 |

1200 |

4 |

BLD 4-2 |

60-100 |

| 1000 |

1200 |

1300 |

4 |

BLD 4-3 |

60-100 |

| 1500 |

1300 |

1400 |

4 |

BLD 4-3 |

60-100 |

| 2000 |

1400 |

1500 |

5.5 |

BLD 5.5-3 |

60-100 |

| 2500 |

1400 |

1500 |

7.5 |

BLD 7.5-4 |

60-100 |

| 3000 |

1400 |

1500 |

7.5 |

BLD 7.5-4 |

60-100 |

| 3500 |

1400 |

1500 |

7.5 |

BLD 7.5-4 |

60-100 |

| 4000 |

1500 |

1600 |

7.5 |

BLD 7.5-4 |

60-100 |

| 5000 |

1600 |

1700 |

7.5 |

BLD 7.5-4 |

60-100 |

| 6000 |

1800 |

1900 |

15 |

BLD 15-5 |

60-100 |

| 18000 |

2000 |

2100 |

15 |

BLD 15-5 |

60-100 |

| 32000 |

3000 |

3200 |

37 |

BLD 37-56A |

35-59 |

|

| Since user¡¯s manufacture technique and operation condition vary, the heating type of jacket can be classified as electric-heating bar, steam and thermal oil circulation. The gland seal packing can be filler seal and mechanical seal. The stirrer has anchor, blade, turbo, impeller or gate types. Drilling number and specification or other requirements can be designed and manufactured as per users¡¯ demands. |

| | | | [Back] [Print] |

×óÐýÈâ¼îÓÐÓÃÂð,

ºü³ôÔõôÖÎÁÆ,

ÌÔ±¦Íøº«°æÅ®×° |

|