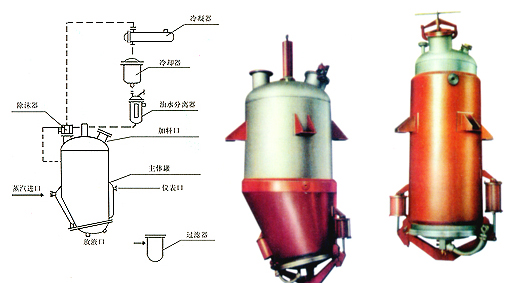

| F-type Extraction Tank Series | | |

[TQ Functions Extraction Tank Series]

The product can be applied in various technical operations in traditional Chinese medicine, foods, chemistry and other industries, including normal pressure, boiling, dipping, thermal backflow, forced circulating infiltration, aromatic solvent extraction and organic solvent reclaiming. It enjoys the advantages of high efficiency and easy operation. The set chooses high-quality materials to widely apply in the volatile oil extraction in pharmacy, foods, chemistry and other industries. |

|

| ¡¡ |

0.5 |

1.0 |

2.0 |

3.0 |

6.0 |

| Total Volume(L) |

500 |

1200 |

2500 |

1200 |

1200 |

Designed Pressure in Tank(MPa)

|

0.09 |

| Designed Pressure in Jack(MPa) |

0.3 |

| Allowed Vacuum in Tank(MPa) |

60 |

| Compressed Air Pressure(MPa) |

0.6-0.7 |

| Feeding Inlet Diameter(mm) |

300 |

300 |

400 |

300 |

300 |

| Heating Area(M2) |

2.4 |

3.1 |

4.2 |

3.1 |

3.1 |

| Condensate Area(M2) |

3 |

5 |

5 |

5 |

5 |

| Cooling Area(M2) |

1 |

1 |

1 |

1 |

1 |

| Filter Area(M2) |

0.25 |

0.25 |

0.25 |

0.25 |

0.25 |

| Equipment Weight(kg) |

1000 |

1500 |

1800 |

1500 |

1500 |

| Outer Size(mm) |

¦Õ1400

¡Á¦Õ2300 |

¦Õ1700

¡Á¦Õ2900 |

¦Õ1800

¡Á¦Õ3700 |

¦Õ1700

¡Á¦Õ2900 |

¦Õ1700

¡Á¦Õ2900 |

| Energy Consumption(kg/h) |

200 |

245 |

325 |

245 |

¡¡ |

|

| | | | [Back] [Print] |

×óÐýÈâ¼îÓÐÓÃÂð,

ºü³ôÔõôÖÎÁÆ,

ÌÔ±¦Íøº«°æÅ®×° |

|