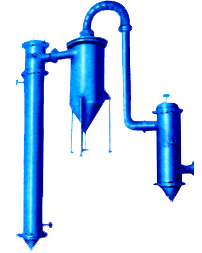

| MB Film Evaporator Series | | |

The device is set up by evaporator, steam-liquid separator, pre-heater and a simple separator. Evaporator is an upward film heat exchanger, which has the features of bulk manufacture, high efficiency and short heating time of material to be suitable for concentrating diluted solution in pharmacy, foods, chemistry and other industries. All parts contacting with materials are made by stainless steel to be good at erosion resistance and durable use, meeting with medicine sanitation requirement. The device is set up by evaporator, steam-liquid separator, pre-heater and a simple separator. Evaporator is an upward film heat exchanger, which has the features of bulk manufacture, high efficiency and short heating time of material to be suitable for concentrating diluted solution in pharmacy, foods, chemistry and other industries. All parts contacting with materials are made by stainless steel to be good at erosion resistance and durable use, meeting with medicine sanitation requirement.

Notes: the high-level tank, rotor flux meter, drain valve, technical valve and pipes need to be afforded by customer. If needed agency, please mark in contract. |

| Main Technical Data |

| ¡¡ |

2.2M2 |

5.5M2 |

8M2 |

12M2 |

16M2 |

20M2 |

30M2 |

40M2 |

60M2 |

M2

Evaporating Area |

2.2 |

5.5 |

8 |

12 |

2.2 |

20 |

30 |

40 |

60 |

M2

Pre-heating Area |

1 |

2.17 |

4 |

6 |

1 |

10 |

15 |

20 |

30 |

MPa

Steam Pressure |

2.4 |

0.4 |

0.4 |

2.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

kpa)

Available Steam Pressure |

6 |

60 |

60 |

60 |

6 |

60 |

60 |

60 |

60 |

| Evaporating Volume |

140 |

350 |

550 |

850 |

140 |

1500 |

2100 |

2800 |

4200 |

kg/h

Energy Consumption |

155 |

385 |

605 |

935 |

155 |

1650 |

2310 |

3080 |

4620 |

| Medium |

¡¡ |

(kg)

Device Weight |

300 |

520 |

750 |

1020 |

300 |

2300 |

2950 |

4500 |

5700 |

(mm)

Outer Size Length * Width * Height |

2000

¡Á850

¡Á3500 |

2300

¡Á800

¡Á3500 |

2700

¡Á950

¡Á4500 |

2000

¡Á850

¡Á3500 |

2900

¡Á950

¡Á5200 |

2800

¡Á1400

¡Á5300 |

3800

¡Á1800

¡Á6050 |

1200

¡Á1800

¡Á5050 |

5000

¡Á2000

¡Á5700 |

|

| | | | [Back] [Print] |

×óÐýÈâ¼îÓÐÓÃÂð,

ºü³ôÔõôÖÎÁÆ,

ÌÔ±¦Íøº«°æÅ®×° |

|